The Manufacturer – As they became known, “Cab Lights” were initially designed and manufactured in the mid-1930s by The Gill Glass Company (hereafter referred to as “Gillco”). Due to the advanced techniques that they developed, the Philadelphia-based company gained a reputation as a high-quality maker of glass fixtures, housings, and lighted glass advertising. Gillco manufactured multiple styles of advertising signs into the late 1950s, when they closed operations.

The “Cab Light” Was Born – As an early entry in the market for illuminated advertising, Gillco produced housings and glass panels for various products including gas globes in the 1920s/30s that were typically used outdoors. They subsequently recognized the growing market potential for indoor lighted advertising and designed a striking three-dimensional sign that was patented in 1936.

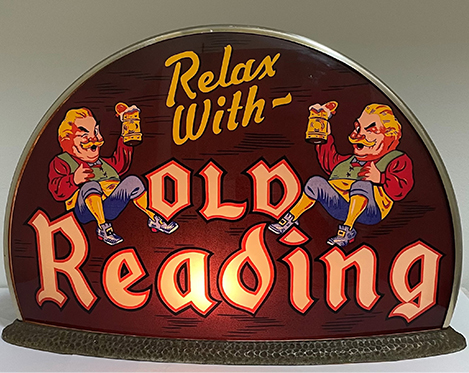

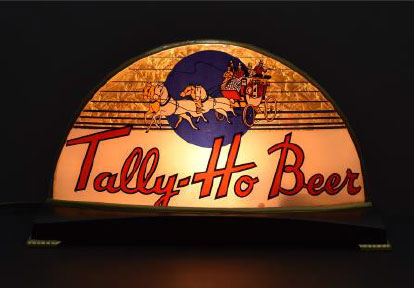

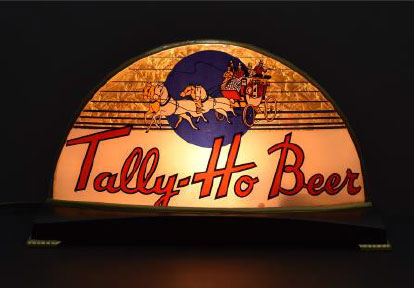

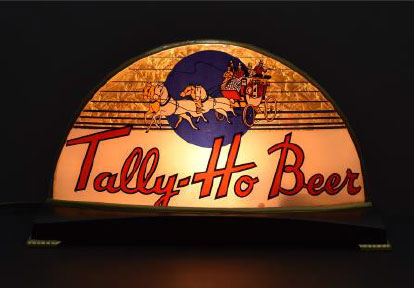

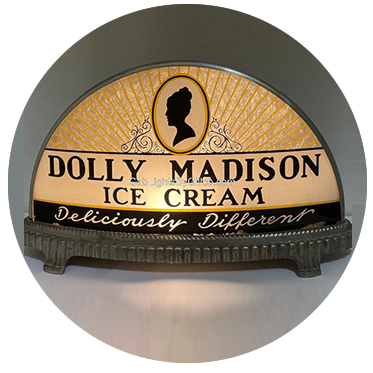

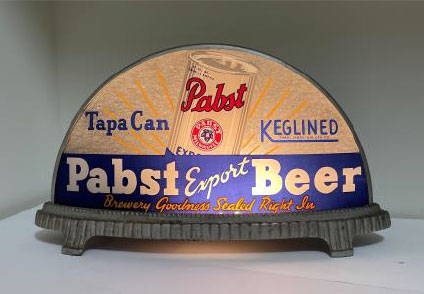

This two-paneled illuminated glass sign was initially referred to as a “Coronet”, but later came to be more commonly referred to as a “Cab Light” due to its dome-like shape which was similar to the lighted signs on the tops of Taxi Cabs at the time.

These Cab Lights, given their promotional appeal in back-bar settings, were marketed and sold to both small and large breweries. In fact, an early purchase order shows that Premier-Pabst ordered batches of three different Cab Lights in January of 1936 with prices of approximately $2.70 each! In addition to the brewery/bar market, Gill Glass also produced Cab Lights as countertop advertising for various other products including ice cream, shoes, eye-care, refrigeration and even for “Storkline Juvenile Furniture and Baby Carriages”.

Despite the high quality and distinctive appearance of the Cab Light, they were only produced for a few years, from approximately 1935 to approximately 1941.

The Manufacturing Process – The phrase “they don’t make them like they used to” certainly applies when considering how Gillco made the Cab Light. Their two hallmarks were graphic appeal and durability.

The graphics of almost all of the Cab Lights that Gillco produced are simply outstanding in comparison to other advertising of the times. The company typically designed advertising that integrated the product with very attractive color combinations. When paired with the mirrored reflective back panels, a three-dimensional effect was created that made a memorable statement when illuminated.

Durability was accomplished through a more expensive painting technique which Gillco likely perfected as they produced outdoor gas globes in the early 1930s. This process involved using a porcelain enamel paint that was fused to the glass. The result was a painted glass advertising panel that was difficult to scratch and was resistant to changes in temperature and higher levels of heat. Consequently, unlike the standard reverse-paint on other lighted signs, the paint on Gillco advertising panels does not “lift” or separate from the front glass.

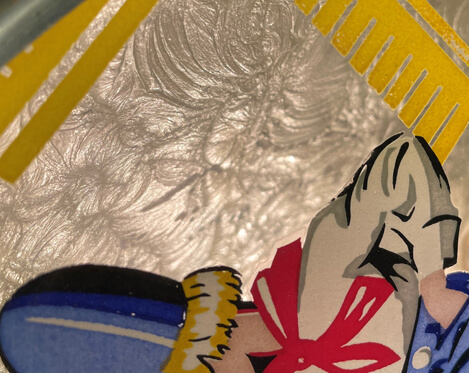

Perhaps in an effort to lower costs, Gillco produced two front panels at a time, using a circular glass disk with two designs laid out. Each round disk was then cut into separate pieces in order to create two front panels so two signs could be produced. One of the pieces was slightly larger and is referred to as the “high profile” style panel, and the other smaller piece is referred to as the “low profile” style panel. Due to the way the panels were cut, it is common to see small chips in the glass at the very bottom of each panel, typically in the middle.

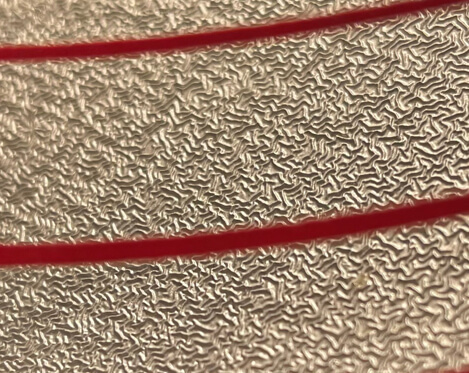

Although some Cab Lights have a front lens that is fully covered with translucent paint, most Cab Lights have portions of the front glass that are clear, enabling a view through to the back panel of the sign. These examples provide more of a three-dimensional look with a back “reflector” lens that typically had a finish similar to silver or gold foil. There were multiple styles of these back lenses with different finishes and the most attractive was a “glue-chipped” texture which reflected light at multiple depths and angles.

Upon completion, the front and back lenses were secured to a metal base with an aluminum “retaining” strap across the top and a light fixture was added to the bottom with the bulb hidden and centered between the glass panels. The metal base was specifically designed and forged by Gillco and at least five different bases were produced. Some of the bases had “dimpled” flat bottoms that sat directly on the counter and others had slightly raised feet. The most ornate version has raised feet with a “ribbed” aka “scalloped” silver base providing a nice Art Deco style appearance.

Overall, Gillco took great lengths and spared little expense to produce a superior sign that was among the most durable and visually appealing of glass advertising signs ever produced. Accordingly, the GILLCO label that was typically applied to the back of the Cab Light is recognized and sought after.